Manas Injection Moulding is an established injection moulding company based in Devon, and has customers from all over the UK as well as the South West and Devon.

We have 4 Haitian Mars machines and 3 well maintained Arburgs that allow us to manufacture plastic components up to 295 grams in weight. Our machines have a clamping tonnage of between 25 - 160 tonnes.

We have over 80 years of experience within the plastics industry, and you will find us helpful and easy to work with. We have a wealth of information and contacts that will help to achieve your expectations.

We also try to help our customers understand the process using layman terminology. We want you to understand the process.

Quality mouldings can be produced for a multitude of industries including medical, construction and electronics.

We operate four Haitian Mars machines and three Arburg machines, ranging from 25 - 160 ton clamping capacity with a maximum shot weight of 295g.

From small batch runs to bespoke medical, engineering and construction products, we provide high quality services.

Based in Paignton, Devon, Manas Injection Moulding supports you during every step of the production process.

MACHINES

YEARS OF EXPERIENCE

MAX CLAMPING FORCE

MAX SHOT WEIGHT

Manas Injection Moulding is an established injection moulding company based in Devon, and has customers from all over the UK as well as the South West. We have 4 Haitian Mars machines and 3 Arburg machines that allow us to manufacture plastic components up to 295 grams in weight. Our machines have a clamping tonnage of between 25 - 160 tonnes.

We have over 80 years of experience within the plastics industry and you will find us helpful and easy to work with. We have a wealth of information and contacts that will help to achieve your expectations.

Meeting customers expectations is the reason we are still in business.

We are ISO9001:2015 UKAS approved and have a material traceability system from material delivery to end product.

We maintain a standard first off/last off check, patrol system, or tailor our system to what our customers require.

We also ensure that the customers tooling is well maintained to ensure low maintenance costs and long life.

Our costing system is a simple to understand break down:

We produce small trial batches to large volume production runs for our customers. We can also assist with tool trialling and proving concepts using prototype tooling. This service is provided to toolmakers and customers bringing tools back from offshore locations.

We can also assist with design and tooling from quality British toolmakers.

We strive to assist from the concept to production of quality components that realise the customers' requirement. From design, material selection to sourcing quality tooling, we can help.

All our machines and equipment are well maintained by a fully qualified maintenance engineer:

As well as:

We use most of the commodity polymers from LDPE to highly engineered metal replacement polymers.

The main polymers processed are:

We specialise in innovative projects, such as those using illuminative materials, and can produce products using general commodity plastics right up to high-grade engineering materials at competitive prices.

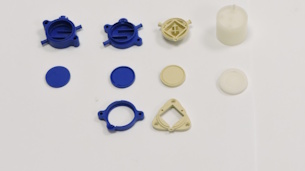

Using our range of Arburg and Haitian machinery, we are able to mould a wide selection of different products from many different types of material. Our gallery shows some of our latest productions and projects.

Our Arburg Selogica machine producing a product out of ABS. You can watch the machine injection moulding a product.